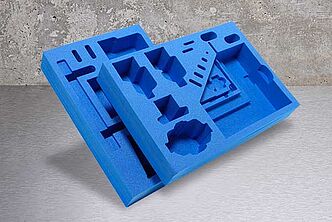

Individual manufactured foam inlays

for cases, boxes, containers and more.

One of the major advantages of foam inlays is the opportunity to individualise the interior design of the case in a unique way and according to your personal application. Whether you want to ensure maximum protection for tools, arrange spare parts clearly in your case or impress your customers with an outstanding presentation of samples during a sales conversation, foam inlays can be used for any type of promotion. Foam is ideal for the protection as well as the optical emphasis and order of products.

Constructive parts for protection or heat- and sound insulation in machines can be manufactured with milled foam. Especially small batches are economically interesting. We manufactured foam inlays and container inserts with the best materials and realise specifications in accordance with high quality standards. Depending on each specification, we make use of the milling technique, waterjet technology, punching technology or shape cutting.

Complete solutions with customised foam inlays

For many years we have collected valuable experience in the production of foam inlays and evolved to one of the leading manufacturers in Germany. In our opinion, customer-friendly solutions should consider feasibility as well as price-performance ratio and quality. For that reason, we produce milled foam inlays in our innovative manufacture in Germany. Guaranteed made in Germany.

TOP QUALITY | MADE IN GERMANY

Individual solutions with foam inlays

30 years of experience in connection with your tasks are the basis for professional solutions with aluminium cases made by KKC.

Here are some examples

KKC guarantee

Made in Germany – we guarantee spare parts and reparations for at least 2 years since the sales date. Solutions by KKC are always a safe investment.Customer service

We are ready to advise you! Make a request and you will get an individual offer in time.Foam inserts for cases and other applications

Foam inserts by KKC Koffer GmbH are very versatile. We manufacture each insert individually according to your specifications, so that each application goal is optimally fulfilled.

Transport security for tools

We are looking forward to manufacture foam inserts for your tool case. These foam inserts are advantageous for securing tools in the case. This prevents the contents of the case from getting mixed up during transport and you finding a mess after opening the case. Sensitive tools are optimally protected in foam inserts. Other organiser systems often work with tabs into which you can insert tools. This allows the tools to be held, but the protection of the tools is not always guaranteed. Also, organiser systems with tabs are usually not customised. Thanks to our individually manufactured foam inserts, your tools are optimally secured and fastened in the case for transport.

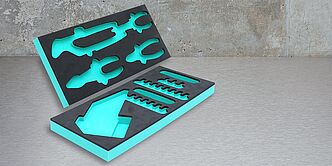

Organise tools clearly

Since the foam inserts are manufactured according to your specifications, you can determine exactly where the tools are to be inserted. This ensures orderly transport of the tools in the case. Especially for the presentation of your products during a sales talk, this can be an invaluable advantage.

Two-coloured foam inserts

If required, foam inserts can be manufactured in two layers. These layers can optionally have two different colours. This allows the viewer to see a different colour than the surface colour when looking into a cut-out in the foam. This colour contrast makes it possible to recognise missing tools. In addition, a clear presentation during sales talks is guaranteed.

Heat and sound insulation in industrial installations

Our foam inserts are also used for requirements other than case design. In mechanical engineering, heat and sound insulation are highly recommended. Our foam is also the ideal material for this. The precise shaping that we can guarantee thanks to our know-how leads to an optimal adaptation to the requirements in this business field as well.

The shaping process

To get our foam inserts into the right shape, we use different production techniques. Our employees have a high level of know-how in the areas of:

- milling technology,

- water cutting technology,

- punching technology and

- form cutting

These production techniques are suitable for different types of foam inserts. In cooperation with our customers, we decide which technique is best suited to their needs and thus ensure that the foam inserts ordered are produced in optimum quality.